The pyrethrum sector has received a boost after an American company, Kentegra, announced plans to put up a modern processing plant in Nakuru that will create 600 direct jobs before the end of the year.

Kentegra Biotechnology is among privately owned firms that were granted a permit to extract, process and sell pyrethrum products when the industry was liberalised seven years ago.

Micah Thuo, the Head of Operations at Kentegra said once completed, the facility is expected to process over 300,000 tonnes of pyrethrum by the end of this year and more than 750,000 tonnes by the year 2025.

The firm, Mr. Thuo said, has contracted more than 2,000 farmers and achieved the highest coverage at more than 600 acres in Gilgil, Kuresoi South and Molo sub counties.

The operations head noted that the country used to dominate the world supply of pyrethrum and added that the entry of the new company is geared to take advantage of the many opportunities in the global market to bring back the yesteryear’s dominance.

“We hope to work with thousands of new and existing pyrethrum farmers to achieve our goal,” said Thuo.

The entry of private companies has shaken a monopoly market that was enjoyed by the State-owned Pyrethrum Processing Company of Kenya in Nakuru.

Other private pyrethrum processors who have been issued with permits are Africhem Botanicals, Pypro and HighChem.

Africhem, which has pitched tent in Gilgil, Naivasha and Molo sub-counties, has contracted 333 farmers with a total of 216 acres. HighChem has 62 farmers and 24.5 acres, while Africhem and Pypro have planted 10 acres each in Kuresoi North and Bahati sub-counties, respectively.

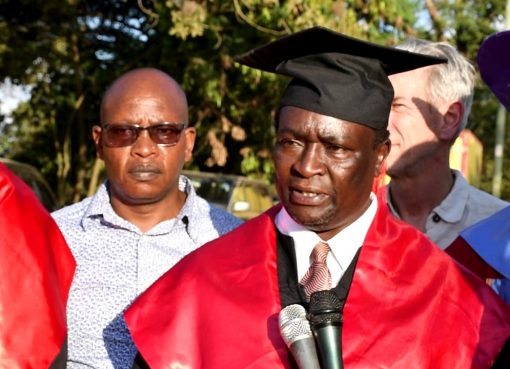

Nakuru Deputy Governor David Kones revealed during a meeting with officials from the American firm that the Company had applied for approvals for construction of the state-of-the-art processing factory that will be based in Naivasha.

He reiterated that the County government was focused on restoring pyrethrum farming as a sustainable source of income for farmers in addition to revamping other agricultural sub-sectors.

While appreciating that 18 pyrethrum-growing counties were keen on establishing an economic bloc to help revive the industry, the deputy governor advised investors in the lucrative industry to rethink their business model by ensuring they set aside enough funds to pay farmers on time.

The counties where the crop is grown are Nakuru, Narok, Nyandarua, Nyeri, Meru, Laikipia, West Pokot, Uasin Gishu, Elgeyo-Marakwet, Nyamira, Kisii, Bomet, Kericho, Kiambu, Trans Nzoia, Murang’a, Kirinyaga and Bungoma.

Mr Kones said reintroducing pyrethrum farming in the region will go a long way towards improving food security through providing regular alternative income to farmers in the county who depend on potato, horticulture and vegetable growing for most of their income.

Instead of opting for a flower variety that grows once a year favoured by developed nations, Kentegra is said to have chosen a variety that produces a flower every two weeks for 10 months in the year. This, Kones added, affords farmers regular cash flow (they are paid a week after delivery) and simultaneously protects their crop with a shorter growth cycle.

He said the county government was leading in action by training more extension workers and was working closely with research institutions including Egerton University and Kenya Plant Health Inspectorate Service (Kephis) to realise the dream.

At the same time, he indicated that Kephis had now been cleared to certify all pyrethrum planting materials and assured farmers that cases of uncertified seeds would be a thing of the past.

The deputy governor added that the county administration was also working closely with the Kephis to ensure the seeds supplied to farmers are certified and suitable for planting in specific areas.

Mr Kones cited under funding of the industry by counties and the national government as one of the major challenges that need to be addressed.

“The pyrethrum sector requires massive funding. Just like the way the government is spending billions of shillings in the coffee and sugar sectors, the pyrethrum industry must be allocated enough funds to save it from the endemic quagmire,” he said.

Kentegra is a United States-based company that contracts farmers and buys dried flowers from them. It started operations in Kenya after signing an investment deal with the Kenyan Government in August 2017.

In January the County Government of Nakuru entered into a collaboration agreement with the United States of America to promote agriculture, technology transfer, trade and investment opportunities that could transform the livelihoods of the residents.

Under the deal, the US government will through the Kentegra network provide a Sh61 million grant to expand the pyrethrum growing base in Nakuru County.

Kenya became the most important supplier to the American market in 1940, shipping the flower in its dry form for processing in America to make a liquid which was, and still is the basis of the best household insecticide.

In 1945, the East Africa Extract Corporation (the subsidiary of Mitchell Cotts, a British trading conglomerate) built its factory in Nairobi’s Industrial Area which, in 1956, managed to achieve a 93 per cent extraction rate, the highest theoretical rate possible.

Pyrethrum production reached its peak in Kenya at 18,000 tonnes in 1993 from more than 200,000 farmers providing a livelihood to more than two million people.

However, in the mid-1990s, the growing use of synthetic insecticides in America (Kenya’s largest market), which were cheaper, had led to a decline in the demand for the commodity. Nevertheless, growing environmental concerns in developed countries over the use of synthetic insecticides contributed to a modest upturn in Kenya’s output in the late 1990s.

By Esther Mwangi and Joseph Karume