Shona Export Processing Zone (EPZ) Limited, a garments firm that switched from manufacturing export apparel to Personal Protective Equipment (PPE )for frontline health workers fighters of Covid-19 virus will be producing masks to meet the local demand.

The Kenyan firm based in Athi River is now manufacturing PPEs ranging from surgical masks, coveralls, aprons and surgical gown in order to heed the national calls on manufacturers to produce the PPEs curb the coronavirus spread.

Officials from the Ministry of Health together with , Kenya Medical and Dentist Council (KMDC) and Kenya Nurses Association (KNU) today conducted a guided tour of the factory , to assess the production of PPEs including face masks.

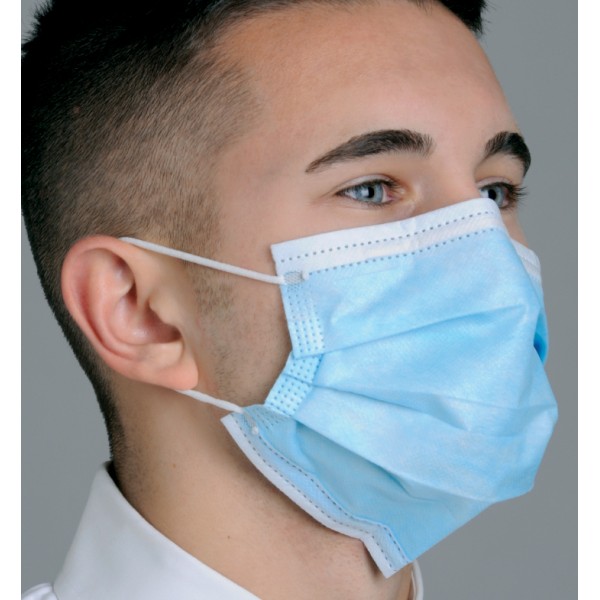

Dr. Eva Njenga , Chairlady of the Kenya Medical and Dentist Council said the issue of mask is very crucial noting that some people are wearing masks that are supposed to be worn by health professionals only.

“Shona is making community masks whose idea is to protect one from passing droplets to other people around”, she said adding that currently all manner of masks are being worn around and even made from homes.

She noted the need for regulation of who is distributing the masks and who has the approval to produce this masks en mass . “ It will be important release a statement from the ministry of health on the kind of masks that have been approved and this should be done sooner than later in order to address the matter fully ”.

Dr. Njenga gave an example of handling of masks through hawking and even in supermarkets where one tries on and if does not fit the mask is returned to the shelves saying it was not proper since already the masks is contaminated.

Dr. Mary Nandile, Director of Nurseing said the production of the masks is going on well and progress shows that excellent work is ongoing , but cited a slight gap on penetration of water that will have to be rectified in order to meet the KEBS standard.

Isaac Maluki, Director of Shona EPZ said they are able to do 20,000 coveralls per day and if need be can also double up their production capacity.

“Currently we are making for testing so that they can get approved and once they are approved then we will go into bulk production”, he said

Governments Spokesperson Cyrus Oguna said they want the PPE to eventually go to the health care workers are County levels as well as community.

“We have been able to look inwardly to determine and assess the potential we have in our local manufacturing industries and currently the three local factories that are making this equipments are Kikotech in Kitui , Bedi Investments in Nakuru and Shona EPZ in Athi River which is undertaking the prototypes now and , once approved, they will now go into mass production.

He asked the Counties health officials to make the purchases for PPEs from those that meet the standard and specification that have been set by the ministry of health so that all of can have equipment that can be able to effectively protect them.

The Governments plan, Oguna noted is to be able to distribute the masks free of charge through the County governments but targeting informal settlements due to socio economic realities in this country.

“As soon as they are ready they will be distributed not to each and every one , but through established structures, through County governments and only to those that are vulnerable members the society”, Col. Oguna said .

Last week Cabinet Secretary Ministry of Trade and Industry Betty Maina said that the government had started manufacturing protective masks and Personal Protective Equipment (PPEs) for prevention against Corona Virus disease.

The Kenyan textile industry has risen up to the task and is currently able to produce as many masks as required including PPEs and ensuring that they are comply with the Kenya Bureau of Standards (KEBS)

By Wangari Ndirangu

Health officials Insist on Certified Masks